News Detail

About the maintenance of the mine dumper, we should pay attention to the following points:

1. It is necessary to replace the high-pressure hose every two years. If the hose is cracked or damaged or partially expanded, it should be replaced in time;

2, should often check the dumping arrangement of equipment is not leakage oil phenomenon. When filling hydraulic oil, check whether the filter installed at the refueling port is damaged, and replace it if necessary to avoid impurities mixing, which will accelerate the wear and tear of hydraulic components or early damage. To prevent the mixed use of hydraulic oil with different trademarks and filling of hydraulic oil that does not meet the requirements of the manual.

3. The underground mine truck should often check whether the meshing and separation of the force extractor and gear pump are normal, so as to avoid the formation of accidental lift of the carriage. Under the operating state, it should also pay attention to whether the vehicle has abnormal sound or abnormal temperature. If necessary, it should be cleaned in time to avoid premature damage to the force extractor, gear pump, valve and so on.

4. When the underground mining truck is repaired, it is necessary to check the working surface of the piston rod of the hydraulic cylinder to see whether there are bumps, scratches and other phenomena. Assuming that there are timely dressing or replacement, otherwise the operating function of the hydraulic cylinder will decline significantly.

5, often check the rear compartment plate locking arrangement is not reliable, underground mining car, and adjust to a reasonable automatic open and close point of view, underground mining car, to avoid the rear compartment plate accident open or lift can not open the situation caused trouble; When dumping large pieces of material, the rear compartment plate should be removed to avoid damaging the rear compartment plate.

6. When repairing underground mine haulers, attention should be paid to cleaning to avoid debris entering the hydraulic system, so as to avoid the occurrence of wear components, blocking valves and other conditions to form the decline of operating functions.

7. If the equipment is out of use for a long time, it should be checked according to the inspection content of the new car before re-use, and it can be reused after passing the test.

8, to often check the chassis car girder and sub-frame connection is not reliable, U bolts and shear iron is not loose, cushion, rubber pad or rubber pad block is not fixed solid, such as loose and dislocation, it is necessary to give fastening and reset.

9. It is necessary to keep the hydraulic oil clean and replace it on time. The hydraulic oil should be accumulated for 48 hours before being injected into the tank. The hydraulic oil filtration accuracy is less than 25μm.

10. The smooth point of each transport part of the underground miner is added with smooth grease on time.

Why Choose US

1. Delievery time: 7 days.

2. Factory price.

3. Three-month warranty.

4. Custom acceptable.

5. Support T/T 30% deposit, Balance before shipping.

Main Features

1. Equipped High Strength Frame

2. High Firmness and Reliability Driving System Assembly

3. Box Frame Structure of Super-Strong Carrying Capacity

4. Comprehensive Optimized Working Device

5. High Energy-Conservation and Efficiency

6. High Safety and Comfort

7. Variety Attached Tools Meeting Requirements of Different Working Conditions

Cheap Price mini mining dump truck for sale.

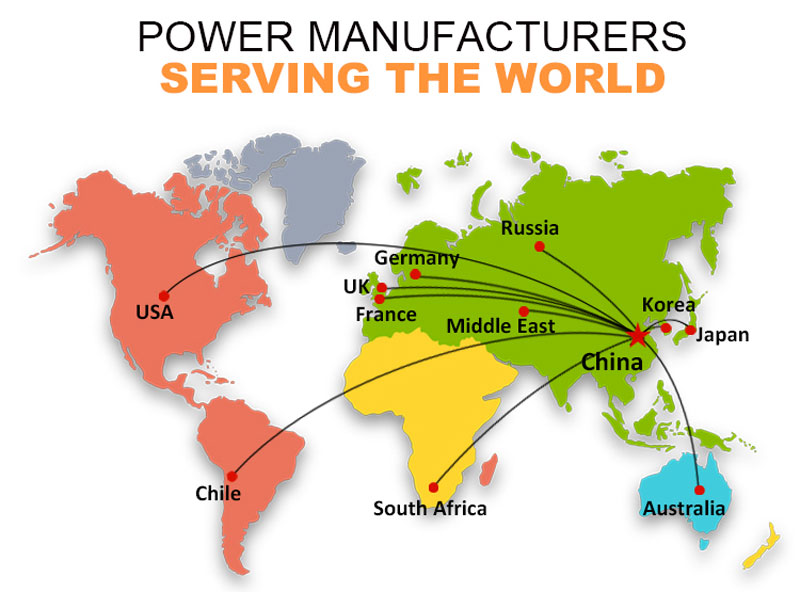

Factory direct sales, 3-12 tons of new mine dump truck for sale, mine product safety certification, qualified certification, efficient, energy-saving, beautiful shape design. Widely used in mine transportation,wood transportation, Stone transportation, etc.. Products are sold to most countries, customers love, low price, quality products, perfect after-sales service, look forward to cooperation with you!